Introduction

In the field of electrical engineering and power distribution, understanding wires joints soldering underground cables is essential. These techniques ensure reliable connections, minimize energy loss, and maintain safety in electrical systems. Whether you’re a technician, electrician trainee, or simply interested in the practical aspects of cable soldering, mastering these skills will give you a solid foundation in electrical infrastructure work.

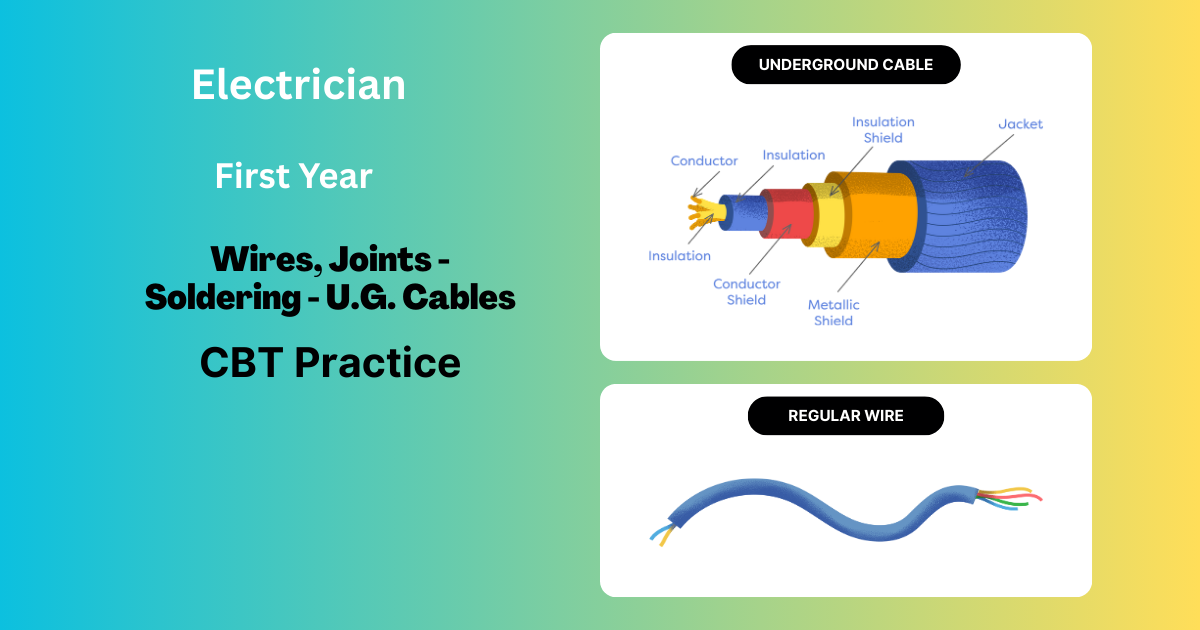

What Are Wires, Joints, and Underground Cables?

Wires and Their Importance

Wires are conductors—typically made of copper or aluminum—that carry electrical current. Their selection and proper installation are vital for the performance of electrical circuits.

What Are Electrical Joints?

Joints refer to the connection between two or more electrical conductors. In the case of underground cables, these joints must be well-insulated and moisture-proof to prevent faults.

Underground Cables and Their Usage

Underground cables are used for transmitting electricity below the ground surface. They are safer and more reliable in harsh environments compared to overhead lines. Wires joints soldering underground cables is a crucial process to ensure long-term reliability and performance in such installations.

Why Proper Joints and Soldering Matter in Underground Cables

Preventing Electrical Loss

Faulty or loose joints increase resistance, leading to power losses and heating. Proper soldering of underground cable joints minimizes such losses.

Ensuring Long-Term Reliability

Underground cables are hard to access once buried. A properly soldered and sealed joint reduces the chances of future failures.

Safety First

Moisture and soil can penetrate improperly joined cables, causing short circuits or even fire hazards. Proper soldering and insulation help maintain safety.

Types of Wire Joints Used in Underground Cables

1. Straight Joint

This is used to connect two cables of the same type and size. Soldering and proper insulation are essential here.

2. Branch or Tee Joint

Used to split one cable into two directions, often seen in distribution networks.

3. Loop Joint

Common in lighting circuits or where temporary disconnection is needed without affecting the main circuit.

Tools and Materials Required for Soldering Underground Cable Joints

Before performing wires joints soldering underground cables, gather the following tools:

- Soldering iron or blow torch

- Solder (usually tin-lead or lead-free)

- Rosin flux

- Insulation tape

- Heat shrink tubing

- Cable jointing kit

- Knife and pliers

- PPE (Personal Protective Equipment)

Step-by-Step Process for Wires Joints Soldering Underground Cables

Step 1: Cable Preparation

Strip the cable ends to expose clean conductors. Ensure the conductors are free of oxidation and dirt.

Step 2: Applying Flux

Apply rosin flux to the stripped ends to facilitate a clean soldering process. This helps the solder to flow smoothly.

Step 3: Soldering the Joint

Use a hot soldering iron or blow torch to heat the joint area and apply solder until the connection is fully coated. Avoid cold solder joints which are prone to failure.

Step 4: Insulation

After the joint cools down, apply insulation using electrical tape or heat-shrink tubing to restore mechanical and electrical integrity.

Step 5: Sealing and Moisture Protection

Use weather-proof sealing compounds or gel kits to make the joint moisture-resistant, which is essential in underground installations.

Best Practices for Soldering Underground Cable Joints

- Always clean conductors before soldering.

- Don’t overheat the cable insulation.

- Ensure there are no sharp edges or wires poking out.

- Use proper jointing kits approved for underground applications.

- Test continuity and insulation resistance after jointing.

Common Mistakes to Avoid in Underground Cable Joints

- Skipping flux: causes poor solder bonding.

- Using the wrong size cables or connectors.

- Inadequate insulation and sealing.

- Reusing old or oxidized solder.

Avoiding these mistakes ensures that wires joints soldering underground cables is done safely and effectively.

Safety Tips While Working on Underground Cables

- Wear insulated gloves and goggles.

- Always de-energize circuits before starting work.

- Keep the work area dry.

- Use a voltage detector before touching cables.

- Follow the standard operating procedure (SOP) for underground cable jointing.

Applications of Wires Joints Soldering in Real Life

- Electrical distribution systems in residential and commercial areas.

- Street lighting and signal systems.

- Industrial power supplies.

- Renewable energy systems like solar farms.

Wires joints soldering underground cables is a critical skill for anyone involved in these systems, ensuring performance and safety over time.

Advantages of Using Soldered Joints for Underground Cables

- Lower electrical resistance.

- Long-lasting mechanical bond.

- Corrosion resistance with proper sealing.

- Flexibility in joining different cable types.

Conclusion

Mastering wires joints soldering underground cables is more than just a practical skill—it’s a vital component in ensuring safe and efficient electrical systems. From selecting the right materials to applying the correct technique and ensuring insulation and sealing, every step counts. Whether you’re an ITI student, a working electrician, or a technical trainer, understanding these core principles is key to your professional development.