Personal Protective Equipment (PPE): Ensuring Workplace Safety and Health

Introduction to Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) refers to devices, clothing, or equipment used by employees to protect themselves from workplace hazards. PPE acts as a last line of defense when engineering or administrative safety measures are not sufficient to control hazards. The Factories Act, 1948, and other labor legislations ensure the proper use of PPE to safeguard workers’ health and well-being.

The primary goal of any safety program is to eliminate hazards through engineering methods, such as ventilation, automation, and mechanical handling. Only when these methods are insufficient should workers rely on PPE for protection. PPE plays a critical role in preventing injuries, illnesses, and fatalities in industrial and construction environments.

Importance of PPE in Workplace Safety

Ensuring workplace safety is not just a legal requirement; it is essential for productivity and employee well-being. Proper use of PPE:

- Prevents common industrial accidents.

- Reduces health risks from exposure to hazardous substances.

- Protects workers from physical injuries like burns, cuts, and fractures.

- Contributes to employee morale and efficiency.

- Helps employers comply with legal safety standards.

Workers must stay informed about workplace hazards and the proper use of PPE. Consistent usage is crucial to avoid preventable accidents. Inspection of equipment ensures that PPE meets quality standards and adequately protects the user.

Categories of PPE

PPE is classified into two main categories depending on the hazard:

1. Non-Respiratory PPE

These protect against injuries from external hazards, including:

- Head

- Eyes

- Face

- Hands and arms

- Feet and legs

- Body

2. Respiratory PPE

Used for protection against inhalation hazards, such as:

- Dust

- Fumes

- Gases

- Vapors

Table 1: Common Types of PPE

| PPE Type | Protection Against |

|---|---|

| Helmet | Falling objects, strikes, spatter |

| Safety Footwear | Hot spatter, falling objects, wet areas |

| Respiratory Equipment | Dust, fumes, gases |

| Arms and Hands | Heat, sparks, electric shock |

| Eyes and Face | Flying particles, UV/IR radiation |

| Protective Clothing | Hot particles, chemicals |

| Ears | High noise levels |

| Safety Belts & Harnesses | Fall protection |

Common PPE and Their Uses

Head Protection

Hazards: Falling objects, striking against objects, spatter.

PPE: Helmets and hard hats.

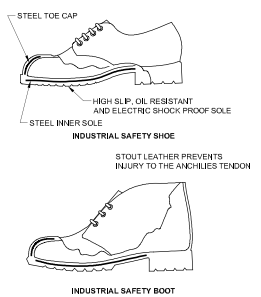

Foot Protection

Hazards: Hot spatter, wet surfaces, falling objects.

PPE: Safety boots, leather leg guards, anti-slip footwear.

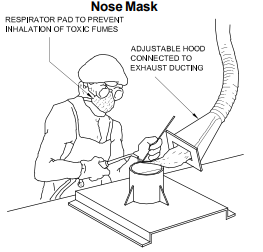

Respiratory Protection

Hazards: Dust particles, fumes, gases, vapors.

PPE: Masks, respirators.

Face and Eye Protection

Hazards: Sparks from welding or grinding, UV rays, flying debris.

PPE: Face shields, goggles, helmets with screens.

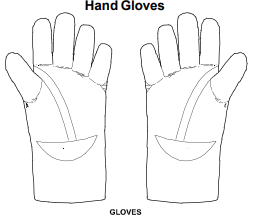

Hand Protection

Hazards: Heat burns, electric shocks, abrasions.

PPE: Heat-resistant gloves, insulated gloves, hand guards.

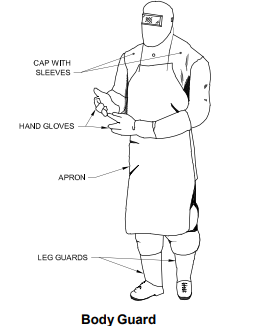

Body Protection

Hazards: Hot particles, chemical exposure, mechanical injuries.

PPE: Protective clothing, coveralls, aprons.

Ear Protection

Hazards: High noise levels.

PPE: Earplugs, earmuffs, head shields with ear protection.

Safety Belts and Harnesses

Hazards: Falling from heights or elevated surfaces.

PPE: Safety belts, harnesses with anchor points.

Quality and Selection of PPE

To be effective, PPE must:

- Provide full protection against the identified hazards.

- Be durable and made of materials suited for specific hazards.

- Be comfortable to encourage consistent use.

- Meet Indian and International safety standards.

Factors to consider when selecting PPE:

- Nature and severity of the hazard.

- Type and concentration of contaminants.

- Work activity and duration.

- Comfort, maintenance, and cleaning requirements.

- Availability of certifications and adherence to standards.

Proper Use of PPE

Even high-quality PPE is ineffective if not used properly. Factors influencing effective usage:

- Employee understanding of the need for PPE.

- Ease of wearing PPE without hindrance.

- Supervision and enforcement of safety rules.

- Education and continuous training on PPE use.

Tip: Make wearing PPE mandatory for all employees, supported by training and supervision to maximize compliance.

Occupational Health, Safety, and Hygiene

Definition of Safety

Safety is freedom from harm, danger, or injury in the workplace.

Occupational Health and Safety

Occupational health focuses on protecting employees and those affected by workplace hazards, including:

- Co-workers

- Family members

- Clients

- Nearby communities

Need for Occupational Health & Safety

Maintaining safety:

- Enhances productivity

- Reduces absenteeism

- Improves employee morale

- Ensures high-quality products and services

Occupational Hygiene

Occupational hygiene involves anticipation, recognition, evaluation, and control of workplace hazards to prevent sickness, injury, and inefficiency.

Steps:

- Anticipation: Identifying potential hazards.

- Recognition: Accepting the possible harmful effects.

- Evaluation: Measuring hazard levels against permissible standards.

- Control: Implementing engineering, administrative, or PPE-based solutions.

Types of Occupational Hazards

- Physical Hazards: Noise, heat, cold stress, vibration, radiation, poor illumination.

- Chemical Hazards: Inflammable, explosive, toxic, corrosive, radioactive substances.

- Biological Hazards: Bacteria, viruses, fungi, plant pests, infections.

- Physiological Hazards: Fatigue, ill health, age, gender-specific risks.

- Psychological Hazards: Stress, aggression, alcoholism, bullying, unsafe attitudes.

- Mechanical Hazards: Unguarded machinery, lack of safety devices.

- Electrical Hazards: Short circuits, current leakage, open wires, improper grounding.

- Ergonomic Hazards: Poor workstation design, manual handling issues, wrong tools.

Best Practices for PPE in the Workplace

- Regular training: Employees should be trained on hazards and proper PPE usage.

- Inspection of PPE: Routine checks ensure that equipment meets safety standards.

- Maintenance and Cleaning: PPE must be kept clean and functional.

- Mandatory Usage Policies: Enforce PPE wearing in high-risk areas.

- Documentation: Keep records of PPE distribution and compliance.

Safety Slogan:

“A safety rule breaker, is an accident maker.”

Conclusion

Personal Protective Equipment (PPE) is critical in preventing workplace injuries and illnesses. While engineering and administrative controls are preferred, PPE remains the last line of defense when hazards cannot be fully eliminated. By understanding types of PPE, selecting quality equipment, proper usage, and workplace safety measures, organizations can ensure occupational health, productivity, and legal compliance.

Remember: Safety is a shared responsibility. Continuous education, inspection, and adherence to safety practices create a culture of protection, safeguarding lives and promoting efficient work environments.