Tools Necessary for an Electrician, Their Use, and Maintenance

Electricians require a wide range of tools to ensure safety, efficiency, and precision in their work. Here’s a detailed look at some commonly used tools, their functions, and care guidelines.

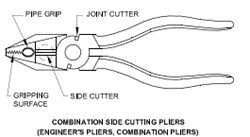

1. Pliers

- Combination Pliers (BIS 3650): Used for cutting, twisting, pulling, holding, and gripping. Insulated handles are used for work on live lines.

- Flat Nose Pliers (BIS 3552): Used for holding flat objects like thin plates.

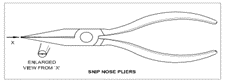

- Long Nose Pliers (BIS 5658): Used for holding small objects in tight spaces.

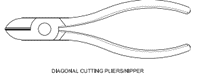

- Side Cutting Pliers (BIS 4378): Used for cutting copper and aluminum wires.

- Round Nose Pliers (BIS 3568): Used for making wire hooks and loops.

Maintenance:

- Lubricate the hinged portion.

- Never use pliers as a hammer.

- Avoid using them on large wires or hard steel.

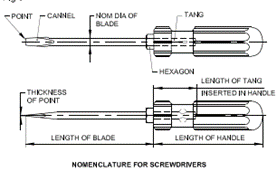

2. Screwdrivers (BIS 844)

- Used for tightening or loosening screws. Available in various sizes, with insulated handles for safety.

- Star-head Screwdriver: For driving star-headed screws.

Maintenance:

- Do not use as a lever.

- Keep the tip sharp and fit properly into the screw to avoid damage.

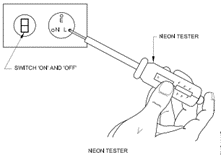

3. Neon Tester (BIS 5579-1985)

Used to check for the presence of electrical supply by glowing when in contact with live parts.

Maintenance:

- Never use for voltages higher than specified.

- Ensure the circuit is completed through the body for safety.

4. Electrician’s Knife (Double Blade)

- Used for stripping cable insulation and cleaning wire surfaces.

Maintenance:

- Keep blades sharp.

- Do not use for cutting wires.

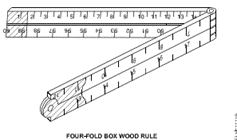

5. Four-Fold Box Wood Rule (600 mm)

- Used for measuring short lengths.

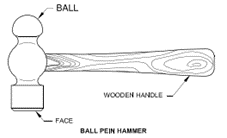

6. Hammer (Ball Pein)

- Used for nailing, straightening, and bending. Sizes are specified by the weight of the hammer head.

Maintenance:

- Keep the handle secure and free from damage.

- Clean the face of the hammer to prevent oil or grease buildup.

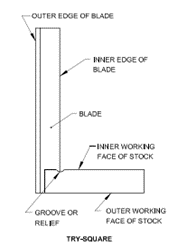

7.Try-Square (BIS 2103)

- Used to check if the object is perpendicular or at a right angle.

Maintenance:

- Do not use as a hammer.

- Ensure it is kept free from damage and rust.

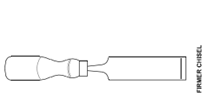

8. Firmer Chisel

- Used for chipping, scraping, and grooving wood.

Maintenance:

- Do not use for driving screws.

- Use a mallet for chiseling.

- Grind and sharpen as needed.

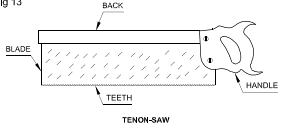

9. Tenon Saw (BIS 5123)

Used for cutting thin wooden accessories like batten or capping.

Maintenance:

- Keep free from rust.

- Apply grease when not in use.

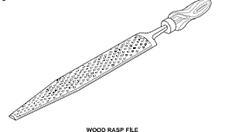

10. Wood Rasp File (BIS 1931)

- Used for filing rough wooden surfaces.

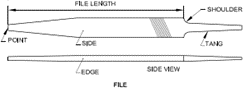

11. Files (BIS 1931)

- Available in various shapes (flat, round, half-round) and grades (rough to smooth). Used for metal filing.

Maintenance:

- Always use with a handle.

- Do not throw as it can damage the teeth.

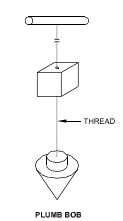

12. Plumb Bob

Used for marking vertical lines on walls.

Maintenance:

- Avoid dropping it, as it may cause damage.

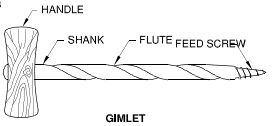

13. Gimlet

- Used for boring small holes in wood.

Maintenance:

- Keep it in a straight position when drilling.

- Ensure it is always sharp.

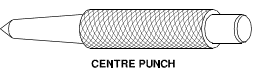

14. Centre Punch (BIS 7177)

Used for marking and punching pilot holes in metals.

Maintenance:

- Keep the tip sharp and properly angled.

- Avoid mushrooms forming on the tip.

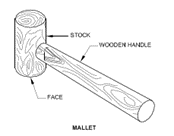

15. Mallet

- Used for driving chisels and in assembly work.

Maintenance:

- Avoid using it on hard metals.

- Keep the handle secure.

16. Ratchet Brace (BIS 7042)

- Used for drilling holes in wood.

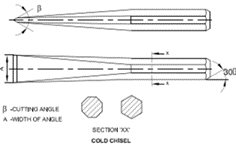

17. Cold Chisel (BIS 402)

- Used for making holes in walls.

Maintenance:

- Maintain the correct cutting edge angle.

- Apply coolant when grinding.

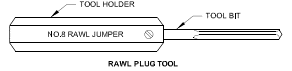

18. Rawl Plug Tool and Bit

Used for making holes in concrete walls for rawl plugs.

Maintenance:

- Rotate the holder slightly after each hammering stroke.

- Keep the tool head free from damage.

19. Spanner (BIS 2028)

- Used for loosening or tightening nuts and bolts. Available in many sizes.

Maintenance:

- Always use the correct size for the nut or bolt.

- Do not use it as a hammer.

20. Ring Spanner and Socket (Box) Spanner

- Used for tasks in confined spaces or where high leverage is needed.

21. Measuring Steel Tape

- Used for measuring dimensions in wiring installation.

Maintenance:

- Handle carefully to avoid damaging the graduation.

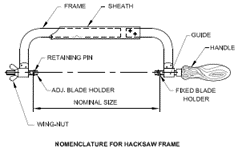

22. Hacksaw (BIS 5169-1986 for frames, BIS 2594-1977 for blades)

Used for cutting metal pipes and rods

23. Hacksaw (for Cutting Metals)

Description: Made from a sturdy nickel-plated steel frame. The frame can be adjusted for 250 mm to 300 mm blades. The teeth of the blade should point away from the handle for effective cutting during the forward stroke.

Care and Maintenance:

- Tighten the blade properly.

- Use a coolant while cutting.

- Ensure the blade is straight during cutting.

- Lift the saw slightly on the return stroke.

- Do not saw too fast

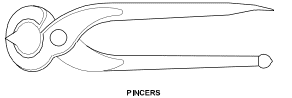

24. Pincers (BIS 4195)

- Size: Available in different lengths such as 100 mm, 150 mm, and 200 mm.

- Use: Primarily used for extracting nails from wood.

- Care and Maintenance:

- Never use the pincers as a hammer.

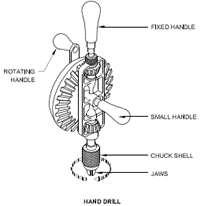

25. Hand Drill

- Size: The size is defined by the twist drill bits that can be fitted in, with typical capacities such as 6 mm or 0-12 mm.

- Use: A hand drill is used for making holes in thin metal sheets or wooden articles.

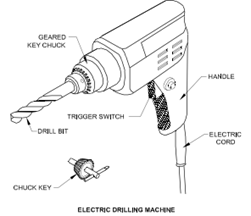

26. Portable Electric Drilling Machine

- Use: When power is available, the electric drilling machine is a more efficient and accurate tool for drilling holes in wooden or metal articles.

Care and Maintenance:

- Lubricate all the moving parts.

- Fix the drill bit securely in the jaws.

- Mark the job with a center punch before drilling.

- For removing the drill bit, rotate the chuck in the reverse direction.

- Avoid applying excess pressure on small drill bits.

- Ensure the electric drilling machine is properly earthed and the insulation is sound.

Each tool has specific maintenance needs to ensure its longevity and efficiency, especially when handling tasks like cutting, drilling, or extracting.

General Care and Maintenance Tips:

- Regular cleaning: Keep tools free from rust and dirt by regularly cleaning and applying appropriate lubrication.

- Proper storage: Store tools in a dry, organized manner to prevent damage.

- Use correct tools for each task: Ensure that the right size and type of tool are used for the job to avoid damage and inefficiency.

By understanding the proper use and maintenance of these tools, electricians can ensure their work is both safe and effective while also prolonging the life of their tools.

1. Standardization and Standard

- Standardization: It refers to the process of formulating and applying rules to ensure consistency, safety, and economy in specific activities. It benefits users and manufacturers by promoting safety, quality, and efficient practices.

- Standard: A defined set of rules, formulas, or physical representations to describe, design, or specify a unit, process, or action. This is essential for ensuring uniformity in products and services.

- ISO (International Organization for Standardization): It provides globally recognized standards for products, services, and systems.

- BIS (Bureau of Indian Standards): Certifies products based on Indian standards, ensuring they meet quality and safety benchmarks.

Advantages of BIS Certification:

- For manufacturers: Streamlining production, quality control, and gaining consumer confidence.

- For consumers: Assurance of product quality and safety.

- For exporters: Easier export processes, reduced inspection requirements.

Advantages of BIS (ISI) Certification Marks Scheme:

For Manufacturers:

- Streamlined production processes and introduction of quality control systems.

- Independent audit of quality control systems by BIS.

- Enhanced product image both domestically and internationally.

- Preference for ISI-marked products by various organizations, including government agencies and private sectors.

- Financial incentives from nationalized banks.

For Consumers:

- Conformity with Indian Standards by an independent, national organization.

- Assurance of product quality and safety.

- Free replacement for substandard ISI-marked products.

For Organised Purchasers:

- Simplified contract negotiations and elimination of the need for inspection and testing of goods purchased.

For Exporters:

- Exemption from pre-shipment inspections and easier export contract negotiations.

Introduction to National Electrical Code – 2011

The National Electrical Code (NEC) 2011 describes various Indian standards related to electrical installations and practices. It is recommended to read the individual parts/sections of the code in conjunction with the relevant Indian standards.

The NEC is divided into 8 parts, each containing a number of sections. Below are the 20 sections of Part 1 and their descriptions:

- Section 1: Scope of the NEC.

- Section 2: Definitions of items with references.

- Section 3: Graphical symbols for diagrams, letter symbols, and signs.

- Section 4: Guidelines for preparation of diagrams, charts, and tables in electrotechnology and conductor marking.

- Section 5: Units and systems of measurement in electrotechnology.

- Section 6: Standard values of AC and DC distribution voltages, preferred current ratings, and system frequencies.

- Section 7: Fundamental principles of electrical installation design and execution.

- Section 8: Guidelines for assessing the characteristics of buildings and their electrical installations.

- Section 9: Design and construction requirements for electrical wiring installations.

- Section 10: Guidelines and general requirements for circuit calculators.

- Section 11: Installation requirements for electrical building services.

- Section 12: General criteria for equipment selection.

- Section 13: Principles of installation and guidelines for initial testing before commissioning.

- Section 14: General requirements for earthing in electrical installations.

- Section 15: Guidelines for lightning protection systems in buildings.

- Section 16: Protection requirements in low-voltage electrical installations of buildings.

- Section 17: Causes for low power factor and guidelines for using capacitors in consumer installations.

- Section 18: Equipment selection for energy conservation and guidance on energy audits.

- Section 19: Safety procedures and practices in electrical work.

- Section 20: Frequently referred tables in electrical engineering work.

This is just a description of Part 1. You should refer to the other parts for more detailed information on electrical installations, devices, and equipment.

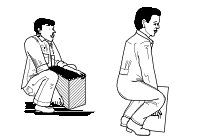

Lifting and Handling Loads

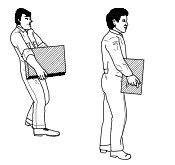

Many accidents in electrical work are caused by improper lifting and carrying of loads. Electricians often need to handle heavy equipment like motors, cables, and wiring, which can lead to injuries if not handled properly. Even if the load seems light, improper lifting techniques can cause muscle and joint injuries.

Injuries Caused by Improper Lifting Methods:

- Cuts and Abrasions: Caused by sharp edges or rough surfaces.

- Crushing of Hands or Feet: Hands and feet should be positioned away from the load to avoid crushing injuries.

- Strain to Muscles and Joints: Lifting too heavy or using improper techniques can strain muscles or damage the spine.

Correct Manual Lifting Techniques:

- Approach the Load Squarely: Ensure the body is balanced, and the load is close to the body.

- Use Legs, Not Back: Lift with the legs straightened and avoid jerking movements.

- Ensure a Safe Grip: Hold the load firmly with both hands.

- Keep Back Straight: Maintain a vertical spine to avoid undue stress.

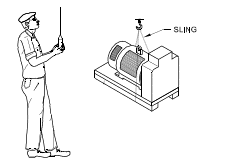

Moving Heavy Equipment:

Heavy equipment in industries is typically moved using:

- Cranes and Slings: For lifting and moving large loads.

- Winches: To pull loads along the ground.

- Machine Moving Platforms: Special devices to move heavy machinery.

- Rollers and Layers: For moving irregularly shaped or heavy objects.

Safety Considerations: Always ensure that all equipment like winches, cranes, and rollers are checked before use, and follow proper safety procedures to avoid accidents.

Summary of Safe Practices:

- Pre-lifting: Ensure the path is clear, and that the load is manageable based on your strength and lifting techniques.

- While Lifting: Keep the load close to the body and use the power of your legs for lifting.

- Transporting Loads: Always ensure safety measures are in place to avoid accidents while moving heavy equipment.